The Future of Manufacturing and Robotics: AI, Automation, and Innovation

Welcome to the cutting-edge world of manufacturing and robotics, where Artificial Intelligence (AI) and machine learning are revolutionizing the way we produce and maintain our daily infrastructures. In this blog post, we’ll dive into the latest developments that are setting the tech and manufacturing industries abuzz. Get ready for a journey of innovation, engineering marvels, and a glimpse into the future that is already here.

Daedalus: Transforming Custom Manufacturing with AI

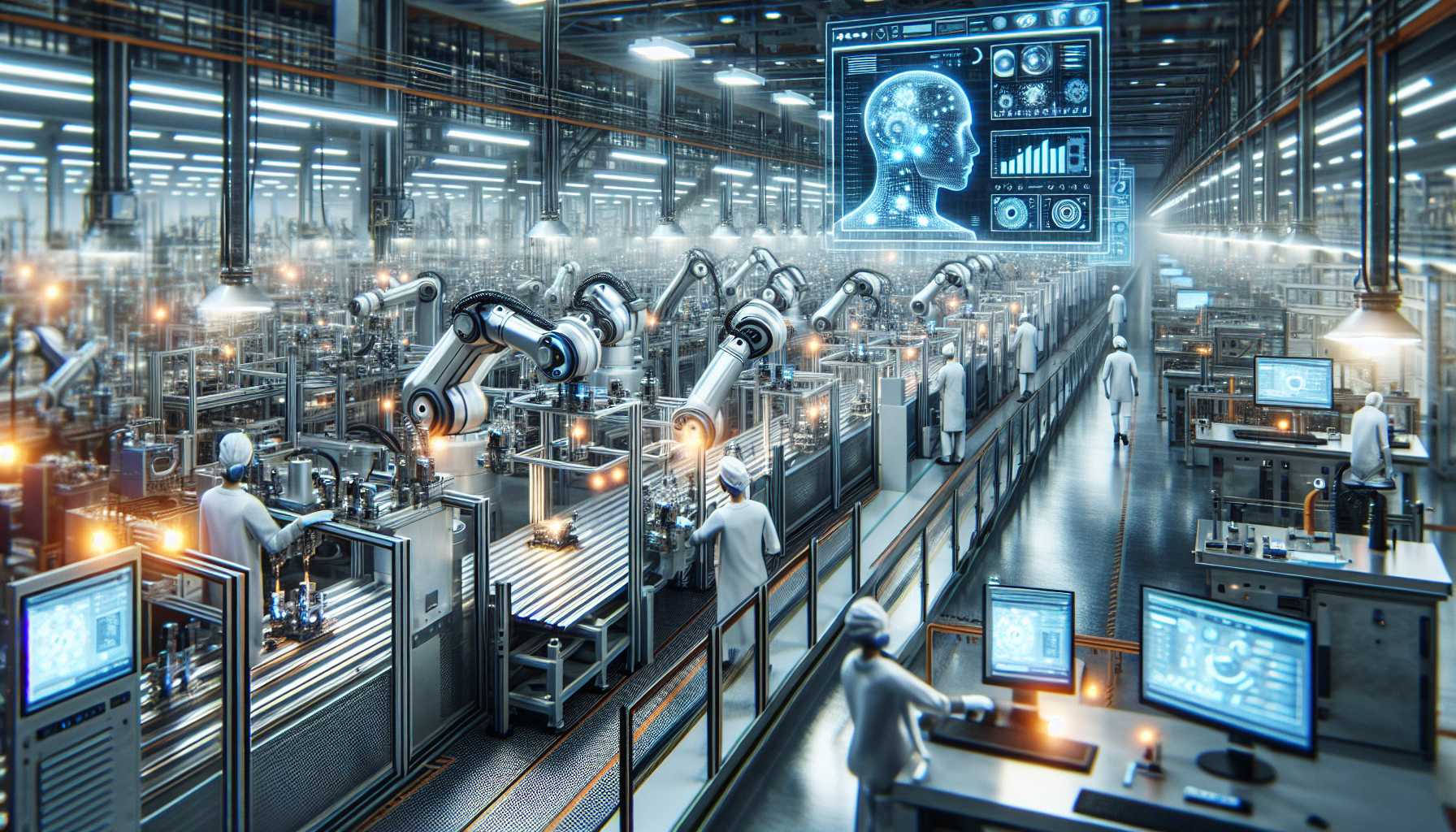

Imagine a world where the limitations of three-dimensional printing are overcome, and advanced manufacturing processes become a reality. This is the vision turned into reality by Daedalus, a startup led by Jonas Schneider, an engineering maestro from OpenAI. Daedalus aims to redefine precision part manufacturing through AI-powered factories that produce bespoke components with unparalleled accuracy.

Based in Karlsruhe, Germany, Daedalus is not just toying with ideas; they’re bringing them to life. Their intelligent software layer orchestrates a symphony of automated tasks, transforming Computer-Aided Design (CAD) drawings into finished parts with such precision that industries like healthcare, aerospace, defense, and semiconductors are lining up for their piece of bespoke perfection.

With a recent Series A funding round injecting $21 million into its veins, Daedalus has surpassed the $40 million mark. This investment underscores the belief that the future of manufacturing lies at the intersection of AI and software. Daedalus has taken the democratized concept of 3D printing, enhanced it with machine learning, and redefined the creation of industrial-grade, high-end parts. It’s an exciting journey that’s just beginning.

CERNquadbot: When Science Fiction Becomes Science Fact

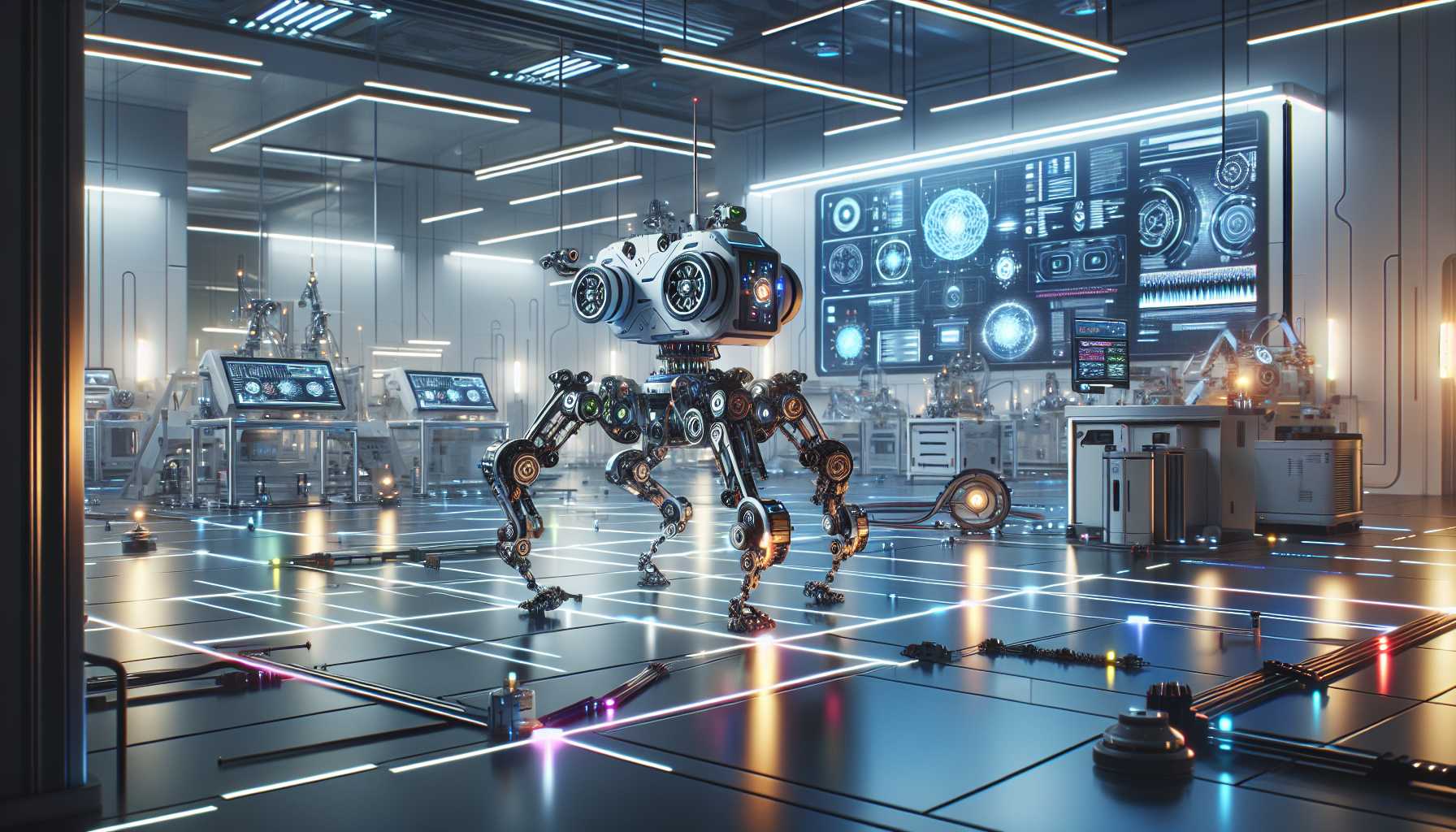

Meanwhile, at the European Organization for Nuclear Research (CERN), the four-legged marvel known as the CERNquadbot has taken the spotlight. While it may conjure images of dystopian robotic dogs from ‘Black Mirror,’ the CERNquadbot’s mission is one of protection rather than destruction.

With its sturdy steel frame and exceptional stability, the CERNquadbot navigates hazardous, cluttered, and sometimes highly radioactive environments within CERN’s vast infrastructure. It partners with other mechanized brethren, like the Train Inspection Monorail (TIM), to explore areas previously deemed too risky or inaccessible for human inspectors.

The CERNquadbot is a technical marvel, showcasing the innovative strides in robotics engineering. It represents a future where machines safeguard human safety in environments fraught with danger.

The Future of Manufacturing and Robotics: My Perspective

As a tech investor and enthusiast, I’ve witnessed firsthand the paradigm shift in the manufacturing industry. The evolution of manufacturing mirrors the constant state of flux in the technology landscape. Daedalus and CERN’s quadbot are prime examples of the exciting strides we’re witnessing.

Their stories captivate not only because of their technological prowess but also because they reveal the vast potential of AI and robotics when applied to real-world problems. Daedalus’ AI-driven factories will revolutionize the production of precision parts, ensuring key industries can rely on efficient, tailored solutions. The CERNquadbot, on the other hand, demonstrates that the robotic revolution extends beyond assembly lines and domestic helpers; it’s becoming an integral part of ensuring safety and progress in one of the most challenging and important scientific arenas.

It’s no exaggeration to say that these advances are paving the way for the next industrial revolution. I, for one, am thrilled to be a part of this journey, witnessing the unabashed geekery, the production marvels, and the robotic aides that might just become humanity’s new best friends. Goodbye, old school – a new era of precision and intelligence is taking over the factory floor. And yes, it is as exciting as it sounds.

Convergence of Ideas, Automation, and Real-World Applications

Both Daedalus’ and CERN’s stories serve as powerful reminders of the boundless potential when ideas and innovation converge. The integration of AI and robotics into manufacturing and scientific research isn’t just about efficiency; it’s about envisioning and actualizing a future where creativity and technology dance in synchrony.

Whether it’s bespoke manufacturing at an accelerated pace or a robot dog traversing the radioactive landscapes of a particle collider, we’re not just witnessing technological advancements – we’re seeing a reshaping of our world. These leaps in innovation are exciting, transformative, and above all, indicative of our human potential.

As industry insiders gaze upon these developments, they do so with anticipation, ready to embrace the next wave of technological transformation. This is what progress looks like: a vision crafted into reality by the hands of pioneers – both human and robotic.

Final Thoughts

As a tech news aficionado and a fervent advocate of innovation, it’s thrilling to chronicle these developments. More than ever, it’s crucial to continue expanding not just our industrial and robotics capabilities but also our horizons when it comes to what technology can achieve.

I leave you with this notion: let your imagination wander, but tether it with the knowledge that the next industrial and robotic marvel could very well spawn from this very moment’s seemingly science-fiction innovations. Stay tuned, stay updated, and let’s keep marveling at this tech-oriented odyssey together.